Inherent

characteristics of control valve

1. EXCLUSIVE SUMMARY

The objective of this experiment is to

study the inherent

characteristics of control valve. To achieve this objective, the apparatus

shown in the figure 1 was used. An equal percentage valve overcompensates for

line loss and produces an effective characteristic that is not linear, but is

bowed in the opposite direction to that of the effective characteristic of the

linear valve. One can show that as the line loss increases, the linear valve will

depart more from the ideal linear relation and the equal percentage valve will

move more closely toward the linear relation. Pressure drop of water in equal%,

quick opening and linear valve are in the range of 101.2 -147.6, 33.6-147.6 and

83.6- 147.6 mm respectively.

2. INTRODUCTION

The control valve is

essentially a variable resistance to the flow of a fluid, in which the

resistance and therefore the flow, can be changed by a signal from a process

controller.

The function of a control

valve is to vary the flow of fluid through the valve by means of a change of

pressure to the valve top. The relation between the flow through the valve and

the valve stem position (or lift) is called the valve characteristic.

In general, the flow

through a control valve for a specific fluid at a given temperature can be

expressed as:

where,

q = volumetric flow rate

L = valve stem position (or

lift)

po = upstream pressure

pt = downstream pressure

The inherent valve

characteristic is determined for fixed values of pa and p 1.

where,

qmax is the maximum flow

when the valve stem is at its maximum lift L (valve is full-open)

x is the fraction of maximum

lift

m is the fraction of maximum

flow.

m = q/q(max) =f(L/L(max))

The types of valve

characteristics can be defined in terms of the sensitivity of the valve, which

is simply the fractional change in flow to the fractional change in stem

position for fixed upstream and downstream pressures.

sensitivity = dm/dx

In terms of valve

characteristics, valves can be divided into three types:

1) Decreasing sensitivity,

2) linear Sensitivity,

3) Increasing sensitivity.

For the decreasing

sensitivity type, the sensitivity (or slope) decreases with m . For the linear

type, the sensitivity is constant and the characteristic curve is a straight

line. For the increasing sensitivity type, the sensitivity increases with flow.

Valve characteristic curves

can be obtained experimentally for any valve by measuring the flow through the

valve as a function of lift (or valve-top pressure) under conditions of

constant upstream and downstream pressures. The linear valve is one for which

the sensitivity is constant and the relation between flow and lift is linear.

The equal percentage valve is of the increasing sensitivity type.

3. OBJECTIVE

To study the inherent characteristics of control valve.

4. Experimental Setup

|

| Control valve set-up |

The setup is designed

to understand the control valve operation and its flow characteristics. It

consists of pneumatic control valves of linear, equal% (& quick opening)

type, stainless steel water tank with pump for continuous water circulation and

rotameter for flow measurement. An arrangement is made to measure pressure at

the valve inlet in terms of mm of water. An air regulator and pressure gauge is

provided for the control valve actuation. In case of additional optional

requirement a valve positioner is fitted on linear valve.

1.

Open the manual

plug valve of equal percentage (air-to-close) control valve.

2.

Open the valve up

to 14 mm travel (full open).

3.

Adjust the

regulatory valve at the inlet of the control valve to maintain the flow at 400

LPH. Note down the pressure drop

4.

Slowly increase

the air pressure by air regulator and close the control valve to travel the

stem by 2 mm.

5.

The pressure drop

across the valve will increase. Maintain the pressure drop by adjusting the

regulatory valve. Observe the flow rates

6.

Take the

observations at each 2 mm stem travel till the valve is fully closed by

repeating the above step

7.

Plot the graph of

flow % of maximum versus valve lift % of full lift

8.

Repeat the experiment for linear

valve (air to open).

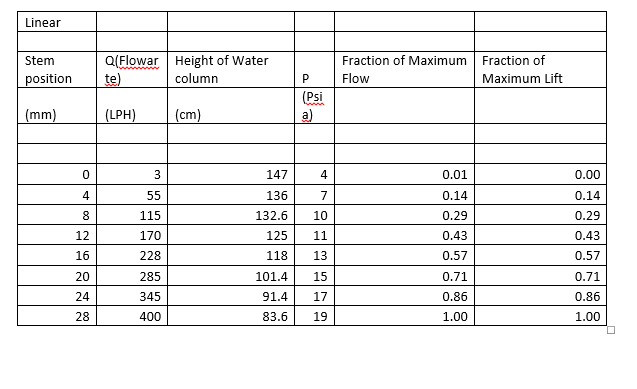

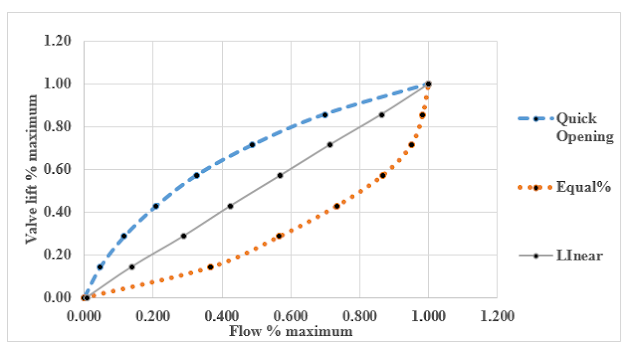

6. Results and Discussions'

|

Inherent characteristics curves for equal%, linear

and quick opening control valve

|

The above figure show the inherent

characteristics of equal%, linear and quick opening valve. Valve lift in

percentage is represent on y-axis and flow in percentage is represent on the

x-axis.

An equal percentage valve overcompensates

for line loss and produces an effective characteristic that is not linear, but

is bowed in the opposite direction to that of the effective characteristic of

the linear valve. One can show that as the line loss increases, the linear

valve will depart more from the ideal linear relation and the equal percentage

valve will move more closely toward the linear relation. Pressure drop of water

in equal%, quick opening and linear valve are in the range of 101.2 -147.6,

33.6-147.6 and 83.6- 147.6 mm respectively.

7. CONCLUSIONS

It is often stated

in the control literature that the benefit derived from an equal percentage

valve arises from its inherent nonlinear characteristic that compensates for

the line loss to give an effective valve characteristic that is nearly linear. An

equal percentage valve overcompensates for line loss and produces an effective

characteristic that is not linear, but is bowed in the opposite direction to

that of the effective characteristic of the linear valve. One can show that as

the line loss increases, the linear valve will depart more from the ideal

linear relation and the equal percentage valve will move more closely toward

the linear relation.

Pressure

drop of water in equal%, quick opening and linear valve are in the range of

101.2 -147.6, 33.6-147.6 and 83.6- 147.6 mm respectively. Gradually close the

control valve in steps of 4mm of stem travel. The pressure drop across the

valve increases.

8.

References

1. Coughanowr

D., LeBlanc S., ‘Process Systems Analysis and Control’, Mc-Graw Hill Science Engineering

Math, 2nd Edition, 2008, P-300-303.