EXPERIMENT

RESPONSE

OF SECOND ORDER SYSTEMS (Step Change)

1. OBJECTIVE

To study the response of second order system

subjected to step change.

2. INTRODUCTION

Second order response

3. EXPERIMENTAL SET-UP

|

| Experimental Setup of second order system |

The

above apparatus used to study the response of second order system subjected to

step change. Two

U tube manometer with water and mercury inside them are used. The inside

diameter of the tube which is filled with mercury is 5 mm and tube which is

filled with water have 22mm inside diameter. Two

valves are provided to control the amount of change. The length of the fluid column in

the manometer is L. At time t = 0, a pressure difference is imposed across the

legs of the manometer and impulsively released.

4.

PROCEDURE

1. The

mercury should be at equal lengths on both the arms

2. The

vent connection is closed by putting a finger on it

3. The

needle valve and the vent are adjusted to raise the mercury to 200mm or above

from the original level

4. Note

the mercury level and remove the finger from the vent and start recording the

oscillations

5. The

process is repeated for different values of step change

6. Repeat

steps 1-5 for water manometer

5. RESULTS

|

| Plots for theoretical and Experimental data for mercury manometer |

Above Figures shows the plot between

the manometer responses with respect to time. It can be observed that the

theoretical and experimental values are different and reach to their steady

state conditions are different response times. System is underdamped with

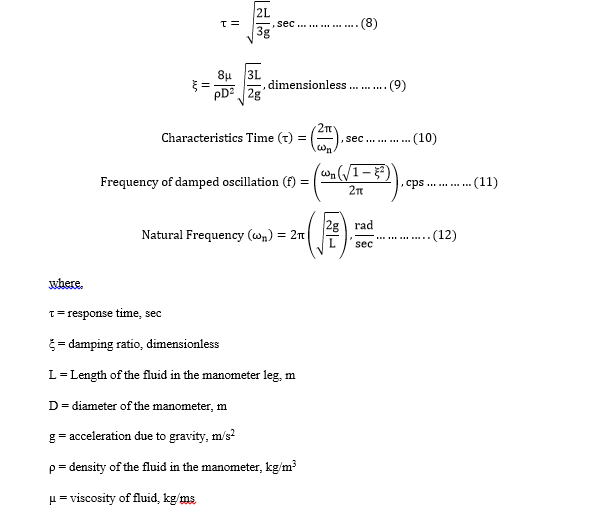

damping coefficient <1. Characteristics Time,

Natural Frequency, Frequency of Damped Oscillations are 0.197, 31.924 and 5.080 respectively. Decay Ratio, Overshoot

and period of oscillation for mercury manometer are 0.911, 0.954 and 0.197 respectively.

|

| Plots for theoretical and Experimental data for water manometer |

Above Figures shows the plot between

the manometer responses with respect to time. It can be observed that the

theoretical and experimental values are almost same and reach to their steady

state conditions are different response times. System is underdamped with

damping coefficient <1. For mercury

manometer, Characteristics Time, Natural Frequency, Frequency of Damped

Oscillations are 0.231, 27.160 and 4.343 respectively. Decay Ratio, Overshoot and period of oscillation

for mercury manometer are 0.953, 0.976 and 0.231 respectively for mercury

manometer.

6.

CONCLUSION

The aim of this experiment was to

study the response of a second order system. The system under consideration was

a mercury manometer and a water manometer. . System is underdamped with damping

coefficient <1. Characteristics Time,

Natural Frequency, Frequency of Damped Oscillations are 0.197, 31.924 and 5.080 respectively. Decay Ratio, Overshoot

and period of oscillation for mercury manometer are 0.911, 0.954 and 0.197 respectively. For water manometer, Characteristics Time,

Natural Frequency, Frequency of Damped Oscillations are 0.231, 27.160 and

4.343 respectively. Decay Ratio, Overshoot and period of oscillation for mercury

manometer are 0.953, 0.976 and 0.231 respectively for water

manometer.

7. REFERENCES

[1]

|

D. R. Coughanowr and S. E. LeBlanc, "Higher-Order

Systems : Second Order and Transportation Lag," in Process System Analysis and Control,

New York, McGraw Hills, 2009, p. 137.

|

[2]

|

D. R. Coughanowr

and S. E. LeBlanc, "Higher-Order Systems: Second Order and

Transportation Lag," in Process

System Analysis and Control, New York, McGray Hills, 2009, p. 141.

|

[3]

|

D. R. Coughanowr

and S. E. LeBlanc, "HIgher-Order Systems: Second Order and

Transportation Lag," in Process

System Analysis and Control, New York, McGraw Hills, 2009, pp.

142-144.

|